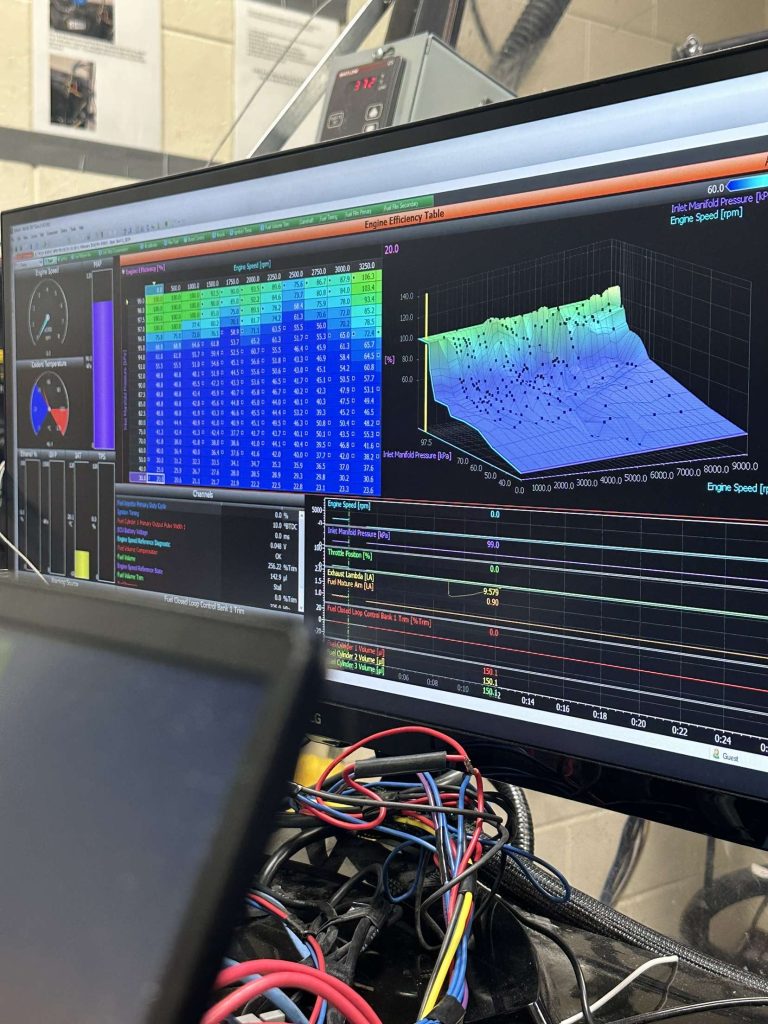

The Advanced Snowmobile Team utilizes two water brake dynamometers at the Advanced Technology Development Complex (ATDC) facility on campus to support both the Spark-Ignition (SI) and Hybrid sub-teams. A dynamometer, or “dyno,” is a specialized testing system that measures an engine’s performance under controlled conditions. By simulating real-world loads, dyno testing allows us to evaluate horsepower, torque, fuel efficiency, and emissions output without requiring on-snow testing.

Benefits/Why our Team Uses Dynos:

- Year-round testing: Since snowfall in Houghton is seasonal, dynos allow us to continue baseline testing, tuning, and validation of our engines even when snow conditions are unavailable.

- Engine tuning and calibration:Both the SI and Hybrid sub-teams rely on dyno testing to optimize fuel mapping, adjust tuning parameters, and evaluate power delivery to ensure peak engine performance.

- Data collection and emissions research: During testing, we gather detailed data on emissions, fuel consumption, torque curves, and power sweeps to improve efficiency and meet competition regulations focused on environmental impact.

- Performance validation: Before our sleds ever hit the snow, we ensure the engines meet competition-ready performance standards and comply with noise and emissions requirements.

By leveraging these dynos, the team can develop, refine, and validate engine performance long before competition season. This capability not only improves our results but also supports our mission to advance cleaner, more efficient snowmobile technology that benefits the snowmobile industry and helps protect the environment for future generations.